Elon was one of the #deletefacebook celebrities. Well, at least Zuck didn’t kill anybody.

Elon tweeted he is going bankrupt. I like his sense of humor. At least isn’t humorless like the Zuckman

Tesla crash, reproduced.

Since I picked up my 3 this weekend, thought I would post my experience.

My experience -

Configuration, setting up delivery, etc: was a breeze. Everything done online or via email. Only a couple of live calls when they called and emailed me to let me know car was ready for delivery.

Actual delivery experience: abysmal. This is the first part where Tesla’s growing pains are showing. I showed up to get my car, after being welcomed and told to take a seat and checking in on me occasionally. Nothing happened. There seemed to be discontinuity of knowledge transfer from person to person. My car had a failure in the final detailing by the techs and no one informed me. After well past my appointment time, I went to check what was going on when the service manager told me they had to swap parts. They offered me an ETA later that night. I said I will be back the following day (good decision). They missed the delivery 3 times the following day as it took them much longer then they expected to get my car ready. and towards the end they would not even give me an estimate (despite my not getting upset till pretty much the end of the following day). After the 3rd failed delivery, i left the place in disgust and they finally called me pretty late in the evening to come pick up.

I came back to pick up, and they told me they will have someone right out, and didn’t. Again after a very long wait (and finally getting pretty ticked off with Tesla) and escalating I got someone to show me to my vehicle immediately. I spent the time doing a pretty long walkthrough as at this point my trust level was pretty low. After the walkthrough I went to do my final docs and they messed up yet again. They brought me someone else’s paperwork. When I pointed it out, they disappeared again for a long time. Finally a manager showed up and she settled everything for me.

Car: So far i am loving it. I have driven a number of small sporty cars - Civic SI, Honda S2000, BMW 335i, SLK 350, and so forth. My favorite car has been the S2000 and I will have to say the Model 3 drives as well as the S2000, accelerates better, quieter then the 335 or SLK. Satisfied with the car so far (early days yet). Upset with their service.

btw I was told that they delivered the highest number of cars ever on saturday in the Fremont location.

Just announce that you’re sleeping at the factory. That’ll make the stock pop even when you miss your goals.

He definitely isn’t lacking in confidence.

It is not a simple task to get reusable rockets (for the most part) out there. It is leadership alright.

This is an epic failure.

It makes you wonder what testing was done at the EVT and DVT stage. Also, what was the trial run for PVT? Did they simply trust the suppliers on testing the parts? Did they do their own testing? Were there a lot of issues, and they just kept moving forward hoping they’d get fixed? They clearly have no clue on manufacturing.

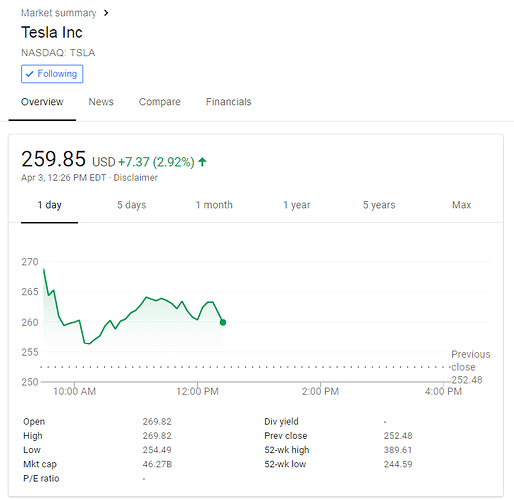

I thought $250 not long ago was a great time to jump in, or to jump back in…

4-5 days is a long shutdown.

It’s seems they don’t know how to run manufacturing when you buy parts from a supplier. There should be specifications. You do DVT to verify the specifications create the results you want, and the DFMEA is right. Then you build tooling for a PVT build. You verify the tooling makes parts to spec, and the PFMEA is right. There should be component, system, and full vehicle level testing. I honestly doubt they do any of it, and they probably rely on a computer model to say the car will work fine. That’s all fine and dandy until you hit the real world with manufacturing tolerances.

It reminds me of when I had to go to a factory because a large percent of vehicles had an issue with a bracket welded onto the fuel filler pipe not lining up to the holes in the body panel. No one analyzed the tolerance stack of the holes in the bracket, the positioning of the weld onto the pipe, and the body panel. On a computer, it works perfect, since you assume every part is 100% made accurate with zero manufacturing tolerance. That’s not the real world. It was solved, and I was home within a week.

It seems Tesla has too many computer screen engineers and not engineers with actual manufacturing experience.

Musk went on record saying Tesla has no need to raise capital this year. I am not sure if that’s really the case. Will see.

He can sell more fancy stuffs. Musky gloves? Elon belts?

Tesla is another stock I don’t understand at all.